Integrating your PLM system with Dynamics 365 ERP is a guaranteed recipe for success. However, when exploring the sea of integration options in the market, you will want to adopt one that maximizes the return on investment and reduces the time to value.

At To-Increase, we offer PLM integrations embedded within Dynamics 365 for Finance and Supply Chain Management. Having implemented integrations for over 18 years in the manufacturing industry, we have interacted with many global enterprises that prefer an easy-to-install/use solution like ours over developing an integration solution.

In this article, we will share how we have built our PLM-ERP integration solutions to be easy for users by preconfiguring and standardizing a significant portion of the solution.

An overview of our PLM-ERP integration for Dynamics 365

To-Increase’s PLM-ERP integration for Microsoft Dynamics 365 Finance and Supply Chain Management is an intuitive, configurable, low-code integration solution that connects third-party PLM, PDM, and CAD systems to Dynamics 365 F&SCM.

Using our solution, you can ensure a seamless data flow between your engineering and manufacturing systems, enabling a quicker time-to-market. With all your engineering and manufacturing information stored in one location, you will have the correct data at the right time to complete production efficiently.

Our solution utilizes specific capabilities of Engineering Change Management (ECM) in Dynamics 365 to better handle product data (revisions, changes, updates).

How does the preconfigured PLM-ERP integration quicken your time to value?

Our preconfigured PLM-ERP integration solutions for Dynamics 365 are simple, ready to use, and adapt to your business needs with minimum configuration requirements.

The solution is built using predefined best practices and developed for specific functional areas within a product's designing, engineering, and production phases. We continuously work toward enhancing the integration solution and execute upgrades in line with Microsoft's upgrade policy, reducing hassles around maintenance.

You deploy the integration solution rapidly, as it has accelerated implementation templates for major PLM providers, reducing the time to go live.

Featuring standard Dynamics 365 functionality, the solution follows the Dynamics 365 business logic. With this, manufacturing companies don't have the pain of coding, avoiding wastage in development hours.

The integration solution saves time, effort, and costs as it can quickly meet the standard requirements for a manufacturing business.

With an implementation time as short as two weeks, companies can gain a swift competitive edge with maximized productivity.

|

Related reading: Should I Build or Buy PLM-ERP Integration for My Manufacturing Business? |

How is the PLM-ERP integration for Dynamics 365 preconfigured?

Several functionalities within the integration solution are preconfigured and standardized. It automates multiple processes that were previously manual and time-consuming.

Here are a few preconfigured processes in our PLM-ERP integration solution:

Transferring product data from PLM to ERP

The PLM-ERP integration leverages the batch server process in Dynamics 365 to automatically pick up and drop off data from the PLM to Dynamics 365. It automatically populates several components of each product by setting up defaults in the template, saving time and effort.

You can also set up periodic checks (for example, every hour) to monitor new data from the PLM.

Maintaining data ownership

During data sharing, the PLM-ERP integration solution ensures that data remains where it should be, as it respects data ownership boundaries. Simply put, the PLM system will always provide the master data for all the engineering-related data, and Dynamics 365 owns and maintains the standard items.

Data is transferred 'as is' from PLM to Dynamics 365 — the PLM integration recognizes any changes within product versions or bill of materials (BOM) lines occurring in the PLM system and automatically updates it in Dynamics 365 without changing any other fields of the product.

Ensuring data quality

The integration solution ensures data quality by validating if the data is correctly mapped to Dynamics 365. Any product data from the PLM system is first validated, processed, and transformed before release.

The product data is released only after the necessary validations are completed. Additionally, you are instantly notified if there’s an error in any product data.

Tracking product versions

In combination with ECM, you can manage complete product versioning. The integration tracks different versions of each product and its sub-parts, offering better control over costs and schedules.

You can carry out local change orders in Dynamics 365, such as adding packaging materials to the existing BOMs. The local changes will be transferred to the latest version when new releases occur, ensuring the product data is continuously updated.

Managing product releases

With ECM and the integration, you can efficiently manage product releases by deciding the amount of product data you want to release to different departments or companies.

The flexible release policies allow you to do part releases, full releases, or release multiple active BOMs for one product by setting up the relevant routings.

Adding product attributes

You can easily add additional data fields or attributes sent to the ERP with a simple configuration to the integration solution. With this, you can get product specifications, such as color, weight, height, and dimensions.

Additionally, you can integrate large data sets and change the product data before importing it to Dynamics 365.

Messaging and mapping of products

Preconfigured messaging and product data mapping are available for two types of flows.

Flow type 1: Message to directly create products or BOMs.

Flow type 2: Message to create engineering change orders (ECO).

These two flows help you analyze the impact of the ECOs on the product. Within the ‘change order functionality in ECM, you can check for any open production orders or sales orders related to the ECO and decide what to do accordingly.

The preconfigured PLM-ERP integration solution in action

Let's look at the solution screenshots to understand better how we have set up standard functionalities in the PLM integration.

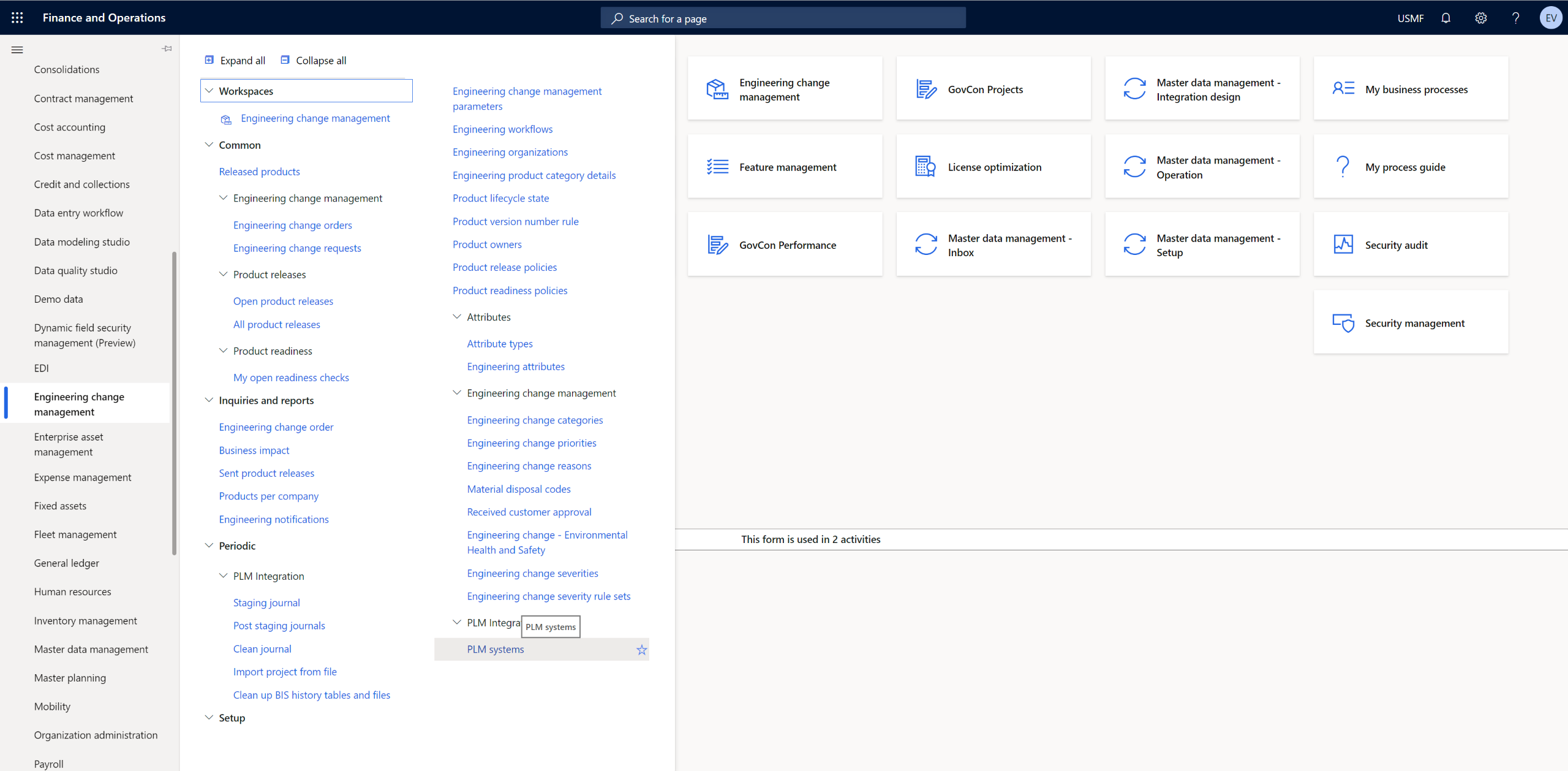

We have built the PLM integration within the Dynamics 365 environment, allowing easy usability. Below you can see the PLM systems in the menu under ECM.

(Click on the image for a full-screen view)

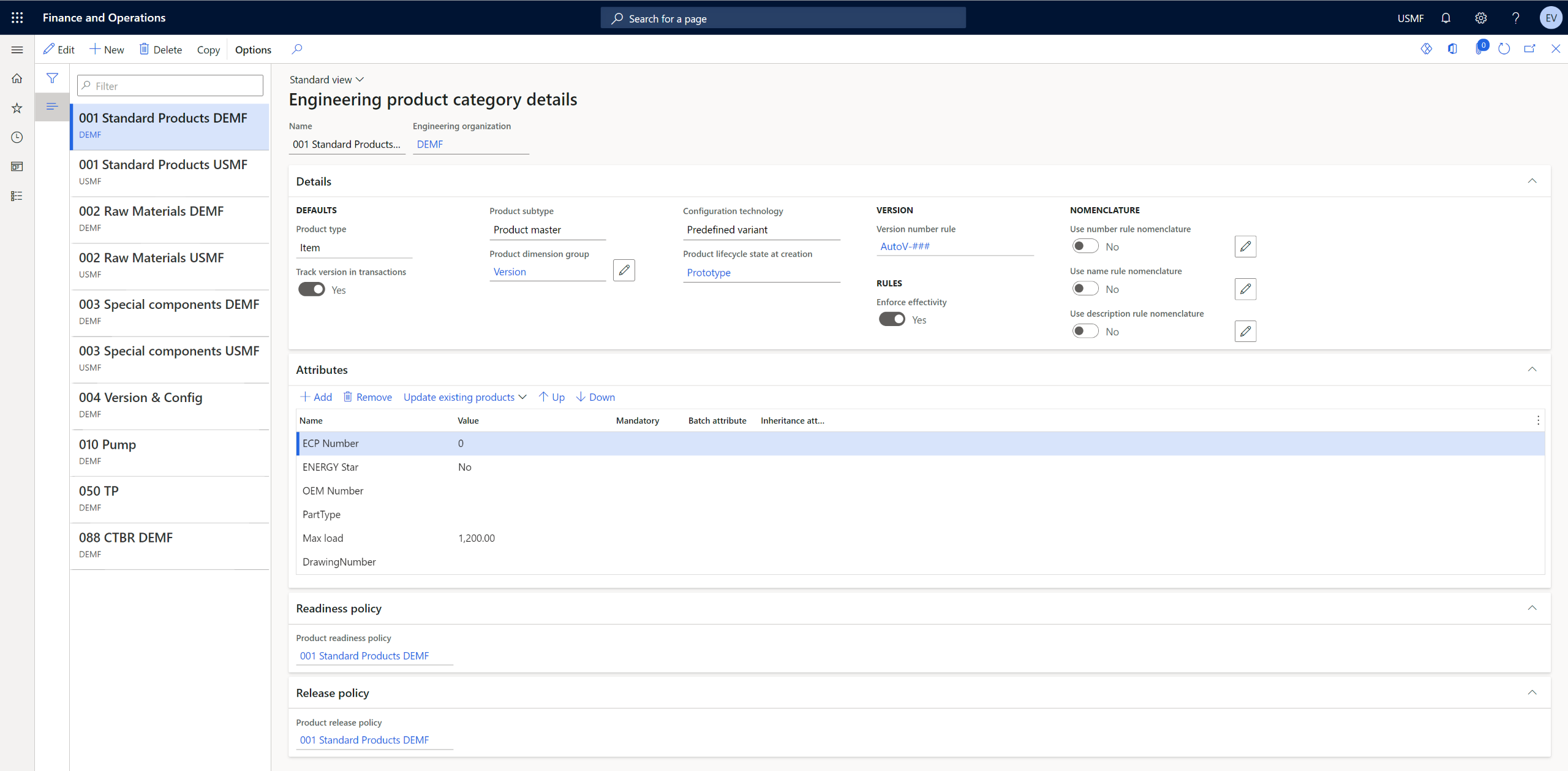

Within the release policy, you can select the type of template you want to use. These templates are linked to the product type. When information comes from the PLM system into Dynamics 365, you can check the data (using ECM) and choose the product category details which hold the template product with the default values (as it uses ECM).

During the release, default values will be taken from the template product on the 'engineering product category details' and automatically set these defaults on the product created. For instance, warehouse setup information, posting setup, etc.

It's also possible to preconfigure product-specific attributes based on the industry or type of product you manufacture.

Below you can see the solution showing the defaults, product attributes, readiness policy, and release policy for a specific product type.

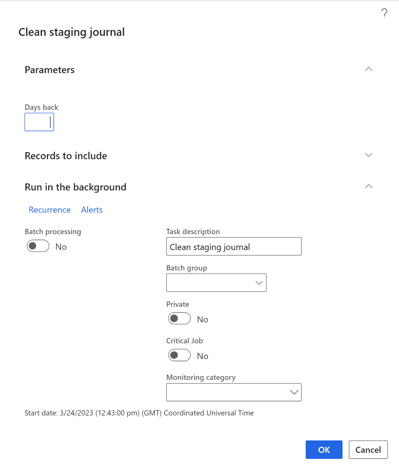

Furthermore, within our integration, activities related to the product journal, such as the staging journal, post staging journal, and clean journal, are preconfigured.

With the staging journal, you can validate the PLM data to check data accuracy, after which the journal is posted.

With the ‘post staging journal,’ you can automatically post journals without manual steps. The ‘clean journal’ can delete outdated journals imported multiple times (thousands of imports).

Below you can see the clean staging journal dialogue box, which shows how you can apply filters to clean journal records and maintain a healthy database.

How does the preconfigured PLM-ERP integration ease user adoption for manufacturing companies?

With a high level of pre-configuration, most business cases only require minor adjustments rather than coding. With our extensive experience, we have defined how data is mapped from PLM to Dynamics 365.

We know precisely which data (type, format, volume, etc.) must be imported, saving time in defining the data. With a combined experience of nearly two decades, our project managers have step-by-step information on the project implementation and know where to place the PLM data in Dynamics 365.

To top it all off, we follow a curated, standard implementation procedure, which includes 5 steps:

i. Analysis

ii. Design

iii. Configuration

iv. Deployment

v. Operation

We provide out-of-the-box standard integrations for PTC Windchill and Siemens Teamcenter, making us well-versed with the data files and XML format for these PLM systems.

For any other PLM, PDM, or CAD systems, we offer a configurable PLM integration framework that can be easily adapted based on business requirements.

Ready to integrate your PLM system with Dynamics 365?

If an intuitive PLM-ERP integration solution with low coding effort and a quick implementation time is what you're looking for, our solution could be the right choice.

Learn more about our PLM-ERP integration solution in the solution factsheet, which shares:

- What the integration solution can do for your business

- Benefits of PLM-ERP integration

-

Features of a standard integration solution