Superb asset management is the heartbeat of successful equipment-driven companies, especially companies that focus on leasing, rental, and services. Whether you’re dealing with an international fleet or diverse machinery and tools, your equipment assets have challenging lifecycles.

You’re looking at lots of customers, lots of usage, all sorts of scenarios and locations. It’s critical to have as much information as possible about equipment performance. Companies started to see the value that the Internet of Things (IoT) brings to the table.

We’ve written in previous articles about how equipment-driven companies can incorporate IoT as part of a rental software solution. We’ve talked also about the benefits of making IoT part of a sustainability strategy for asset management, and about specific ways to use IoT for predictive maintenance. We encourage you to explore those articles; for this piece, let’s take a focused glance at how using IoT can lead to longer, more profitable equipment lifecycles.

Anytime, any location, IoT can tell you what’s happening with your equipment

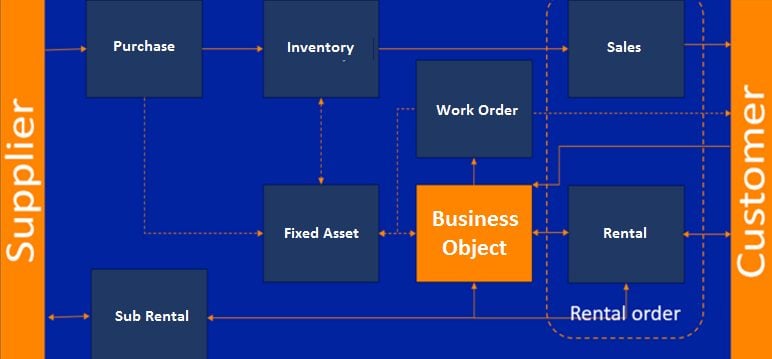

Mobile sensors or devices can be attached to virtually any part of your equipment. They can collect data that measures anything you need to know to optimize utilization and maintenance. What’s proving so effective about computerized equipment monitoring is that it can feed into your rental and service management system. It can emerge as “the story that makes sense” for a given piece of equipment. From oil levels to operational stressors to environmental conditions, you have both a 24/7 feed about real-time equipment behavior and needs. You also can build a history that links to customers, usage, locations, operators, and longer-term equipment behavior.

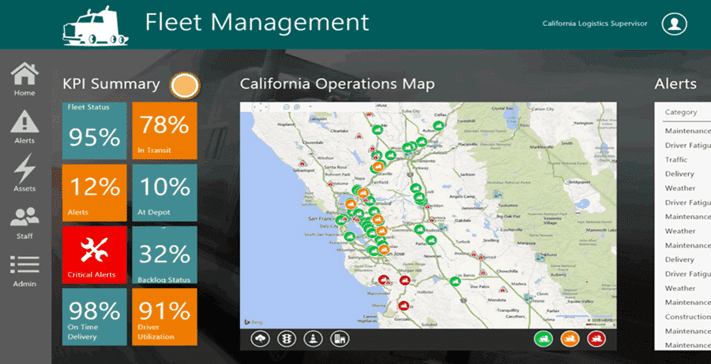

As a result, IoT gives companies the information they need. This way they can streamline predictive maintenance. So that it’s executed much more precisely. You can analyze and better anticipate breakdowns. Know what equipment works best under what conditions. Even what operators may need fine-tuned training so that they use equipment better. And of course, you’ll be alerted on the spot if something’s gone awry and emergency service is needed. Thanks to IoT, you can have a tech in the field before the problem is even a visible one.

Image 1: Complete IoT dashboard for a company that increases their equipment lifecycles via the Internet of Things

Benefits translate directly into savings such as:

- Reduce your equipment down-time. Service is proactive and tuned to actual situations.

- Lower maintenance costs, thanks to reduced manual overhead and streamlined service.

- Increased utilization rates: Better service, smart allocation and re-allocation, best operators, etc.

- Longer equipment lifetime: IoT helps you know all angles needed for best long-term usage and performance.

There’s also the added benefit of overall reduced overhead for equipment lifecycle monitoring. You can turn manual monitoring into more actionable roles. And if you’re on a growth path, invest in equipment and staff. This will let you take on more customer opportunities.

Takeaway?

Incorporate IoT into you rental management system. A sure bet for your reputation and your financial profits? We think so.