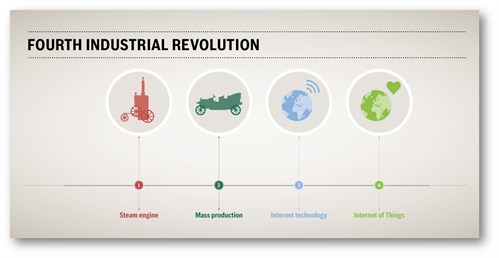

As the internet of things (IoT) rapidly ushers in the fourth industrial revolution, companies begin to think differently about products and information-sharing with other businesses. Given the potential for outstanding customer experiences and steadily improving product designs with greater reliability and better performance, industry innovators are embracing the IoT. For many companies, the possible gains in productivity enhancements, new service business models, and operational transparency outweigh the risks that come with more liberal information-sharing.

IoT-driven, fully digital Industry 4.0

In this blog, we have repeatedly discussed the IoT and its key role in assisting companies to create systems of engagement and deliver a high-quality customer experience from different angles. Even since the first IoT-related post in October 2014, the momentum of the IoT has become more rapid and intense. Analyst forecasts for the IoT offer increasingly astronomical numbers. A common figure is the projection of 30 billion sensor-enabled objects connected to networks by 2020. This is only a subset of the expected total of 212 billion objects that will be sensor-enabled at that time. That means roughly 28 sensor-enabled devices for each person alive.

Generational change drives IoT adoption as the millennials assume center-stage. They are used to living in a connected world, where almost any resource or content is available on any device at any time, connectivity is part of the natural environment, and people, services, and businesses are always within reach. Technology thinkers and planners at such industry leaders as Microsoft and Bosch talk about the IoT, along with advanced robotics, as a main enabler of the fourth industrial revolution or Industry 4.0.

Evolving manufacturer/customer relationships and interactions

At To-Increase, we expect the IoT to be prominent in the lives of the people who run the manufacturing companies and other businesses that run our solutions. For example, the business-critical machines in many manufacturing businesses will be connected within the IoT. When you review the performance of a machine on your preferred device, you may find that a power supply is developing a problem. You can initiate a repair or replacement, and forestall failures of the same-model power supplies in other machinery. Or, you may notice that your IoT-connected machine that executes on a recipe is not working within acceptable tolerances. You have your vendor perform a recalibration, but then you also engage with that vendor in the development of an enhanced calibration module that will be designed, tested, and revised based on IoT data.

In upcoming blog posts we will more closely examine such possible business scenarios and elevated customer experiences enabled by the IoT, including predictive maintenance and new service models.

Expanding the horizon of machinery and other products

The IoT and its great variety of possible usage scenarios prompt a new thinking about the nature of products. I expect this to keep pace as IoT-driven innovation spreads from the early adopters across industries. In a first step, we are moving from ordinary, functional products to smart products that can collect, store, and present data about their utilization and performance to a person who audits them. As smart, connected products they also can transmit that information to computers and devices within the networks of the company using them as well as their manufacturers. When they become part of a product system, such as the different types of machinery at a food manufacturer or the agricultural machines in our illustration, more varied product data can become relevant to more people and processes.

At that point, you can rely on machine IoT data to manage the dependencies in the usage of different machines as well as other resources, perform more reliable and more proactive planning for maintenance, materials, and parts, or introduce business-wide productivity improvements. Finally, when the product system that includes this machine integrates within a system of systems, you also gain the ability to manage manufacturing cycles in close coordination with suppliers and contractors, plan deliveries in sync with customers’ schedules, and improve planning with holistic business intelligence.

Next: We look at some ideas and planning concepts for generating revenue from the IoT.

In the meantime, please share your ideas, feedback, and questions. Get in touch with me or contact To-Increase.

Do you want to get started today? Start your transformation into the cloud today with our free whitepaper.