Equipment transport management companies that transport high volumes of smaller equipment work, quite literally, in a sea of moving parts. To start, a single equipment offering can require picking and assembly of dozens of items. Consequently, rental orders might be relatively uncomplicated. But there are a lot of them, coming from many customers who each expect quick time to delivery. Returns at end of rental periods are constantly in process. They have the need to efficiently receive items and scan them into the ERP system. Not to mention need to quickly document missing parts and determine what items need servicing. What can go straight to a new customer? Or back to the warehouse/depot, etc.

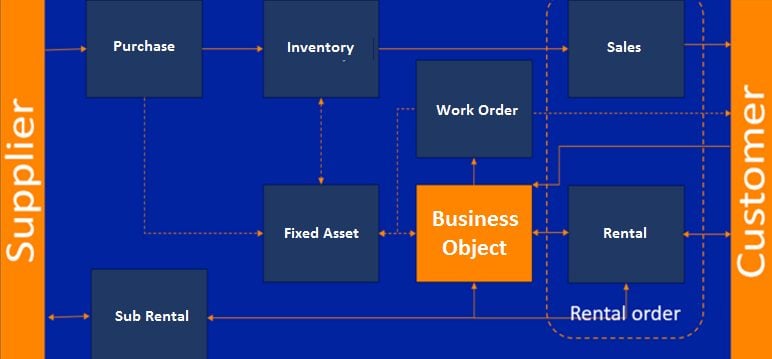

Keeping all parts moving in the right direction calls for oversight. Which is built on integrated equipment transport management and warehouse operations. Particularly it’s important to work with a equipment transport management solution that fits seamlessly with Dynamics AX warehouse management. Especially for companies using Microsoft Dynamics AX. With the right solution in place, transport planners and warehouse staff can collaborate in real time to align picking, packing, and shipping. As well as process returns with speed and accuracy. Benefits of integrated equipment transport and warehouse management are:

Transport planners have full insight into warehouse processes

We’ll use a scenario to illustrate. A batch of orders from different customers that requires organizing and shipping 2000 items to 25 locations. Using the transport management solution’s graphical planning board, transport planners can view much more than orders and delivery locations. They’ll also have summary views and full drill-down into warehouse progress for picking, assembly, and packing for orders. Estimated time to completion is always visible and changes dynamically as work progresses. Planners have what they need to schedule resources and define delivery routes.

Departments can collaborate to manage delivery priorities issues strategically

If x set of customers are expecting delivery within 24 hours, then planning and warehouse staff can communicate easily about that priority and make sure that inventory staff prioritizes picking, packing, and assembly for units and spare parts for those customers. If issues and opportunities come up they can orchestrate resolution. For example, transport planning finds they have surprise capacity on trucks to cover part of the 24-hour shipment. They can check warehouse progress and alert them to send finished orders to pick-up docks immediately—partial shipment can be executed early!

If, on the other hand, warehouse uncovers an inventory shortage, they’ll know to prioritize the 24-hour shipment and transport will be alerted if that shipment is impacted by the shortage. Transport in turn can plan for staggered shipping for the most efficient fulfillment, and if needed communicate with customers (or the rental department) if shipment will actually be delayed. At all times, departments are in sync and work together.

Collaborative transport and warehouse management speeds efficient, accurate returns processing

Rental equipment lifecycles require a close eye across all phases to optimize utilization and drive flawless service, including inspections, maintenance, and service. Warehouses and depots need to know what’s coming in, when, from what location, and in what condition. Transport solutions that integrate with ERP and extend to TomTom integration connect planners, logistics, and drivers into a smooth rhythm. Warehouse can view organized transport information and instantly know the status of equipment returns, driver inspections, and other details that fuel quick receiving and processing. They can communicate with drivers directly via TomTom, with assurance that transport has firm control over driver information and their tasks—nothing is ad hoc.

With well-integrated equipment transport and warehouse management, your company can navigate all the moving parts for rental, leasing, and services—no worries about parts flying about in all directions. For more glimpses into equipment transport management trends and solutions, explore our articles about transport collaboration and working with third-party carriers.

Curious?

Curious about our expertise with equipment transport management for your specific industry? Please do contact us to discuss how we can help you incorporate digital transformation into your business.