Manufacturing Integration

For Microsoft Dynamics NAV

For project-based manufacturers that run all activities related to customer orders from within Jobs in To-Increase Industrial Equipment Manufacturing, Manufacturing Integration makes broad user productivity improvements possible. The solution offers an arsenal of tools to enable greater visibility in production planning and workload management, better control over subcontracted Jobs, and enhanced progress monitoring.

When you deploy Manufacturing Integration, you can run production orders in your preferred manner—from independent, where the production department figures as an internal supplier, to fully integrated in a Job. Full integration entails exploding your bills-of-material in the Job Planning Lines, where you can modify them to create Job-specific production orders. You can transfer work in progress from production to Jobs by posting production order consumption to a Job.

Manufacturing Integration lets you use the same resources in production as in Jobs and Service, and gain a unified view of their activities. Link resources to a machine center and thereby set the machine center’s capacity. Add resources to routing operation steps, in the routing, the production order routing, or from the Visual Production Planner.

Advanced manufacturing settings in Manufacturing Integration augment the control and versatility of Progress Registration, Subcontracting, blanket order planning, and production item cost calculation.

Download the Manufacturing Integration factsheet

Manufacturing Integration for Microsoft Dynamics NAV

Features

Blanket Purchase-Order integration

Include Blanket Purchase Orders in your supply calculations. A planning request within the shipping date consumes supply from Blanket Orders, and a requested shipping date later than the vendor’s lead time generates a Blanket Purchase Order.

Maintaining production-line relationships

A Manufacturing Integration feature called Update Multi-Level Planning Production Orders ensures the mutual dependencies between production lines. Moving one line in time also shifts related lines automatically.

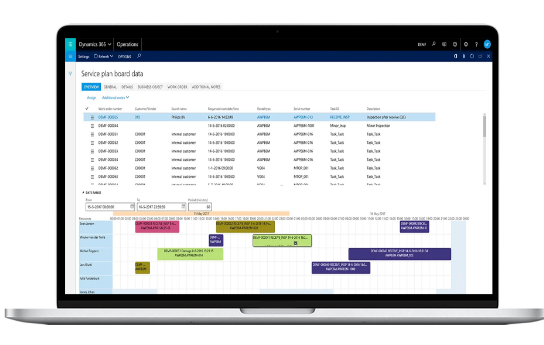

Visual Production Planner

Visualize your production planning with the solution’s Visual Production Planner, and assign resources to operations by simple dragging and dropping.

Enhanced Subcontracting

You can control subcontracting workflows and receive warnings if previous processes are not finished.