The manufacturing business is full of challenges regardless of whether you are into heavy equipment manufacture, mass-produce standard products, or into engineer-to-order products. It is, therefore, important to focus on improving the efficiency of your operations. In this article, we will look at the top five manufacturing software aspects that will help you stay efficient.

Using these solutions, you can manufacture innovative products, high-value, ETO, or complex products. Here is the list of production management solutions that you should focus on to meet production requirements:

- A connected cloud-based ERP solution: When you are in the business of manufacturing, you cannot afford to have different systems that operate in isolation to support your operations. Though these solutions may offer specialized support, your teams may find it difficult to retrieve and update information in different systems. When the solution you use can provide complete support for your requirements in a single environment, then you can see the results quickly. And when the solution is on cloud, deployment happens faster, functionalities are enabled, and you can save on resources for hardware and networking technologies. For cloud solutions, upgrades and integrations are also quicker and easier. Today, you have manufacturing solutions that can be easily deployed using configuration instead of coding for any gaps you may for the functionalities that are missing.

- Integrating manufacturing and engineering: As you know, ERP powers manufacturing and PLM (product lifecycle management) helps manage the engineering, design, and other technical aspects of the product. In many companies, PLM is not integrated with ERP and this can lead to manual updates, rework, lack of shared data, and thereby losses. When you have changes requested by the customers and have been updated in PLM but not to the ERP or vice versa, there would be a gap in the product specifications leading to a cascading effect. Procurement would not be aware of the material requirements and there would be plenty of rework.

- Mobility enabled solutions: The whole world is on mobile, which is making distances seem like nothing. Imagine if you can replicate the same ease, immediacy, and convenience to your work bringing together production shop floors, warehouses, branch and main offices, and more together. The field staff would find it easy to access the solution and update details while on the move. There would be little lag in the way updates are followed up and acted upon. Today, technology has enabled functionality without compromising on security or convenience. The transformative effect that mobility can bring to your operations can be far-reaching and profound.

- Functionality quote prices: In manufacturing, one of the most important aspects is the ability to configure the requirement that a client has, price it correctly and send the quote. The product configuration has to be viable and all the aspects need to be checked before you can rate it and share the quote. When you follow this process manually, there is a chance for errors occurring, some details being missed, and a lot of rework. With configure-price-quote (CPQ) functionality, you can move from the initial talks to the quote level, which can be converted to the engineering and manufacturing bill of materials (BOM). The CPQ feature will ensure that production and design can work in tandem and that any changes are duly noted and updated.

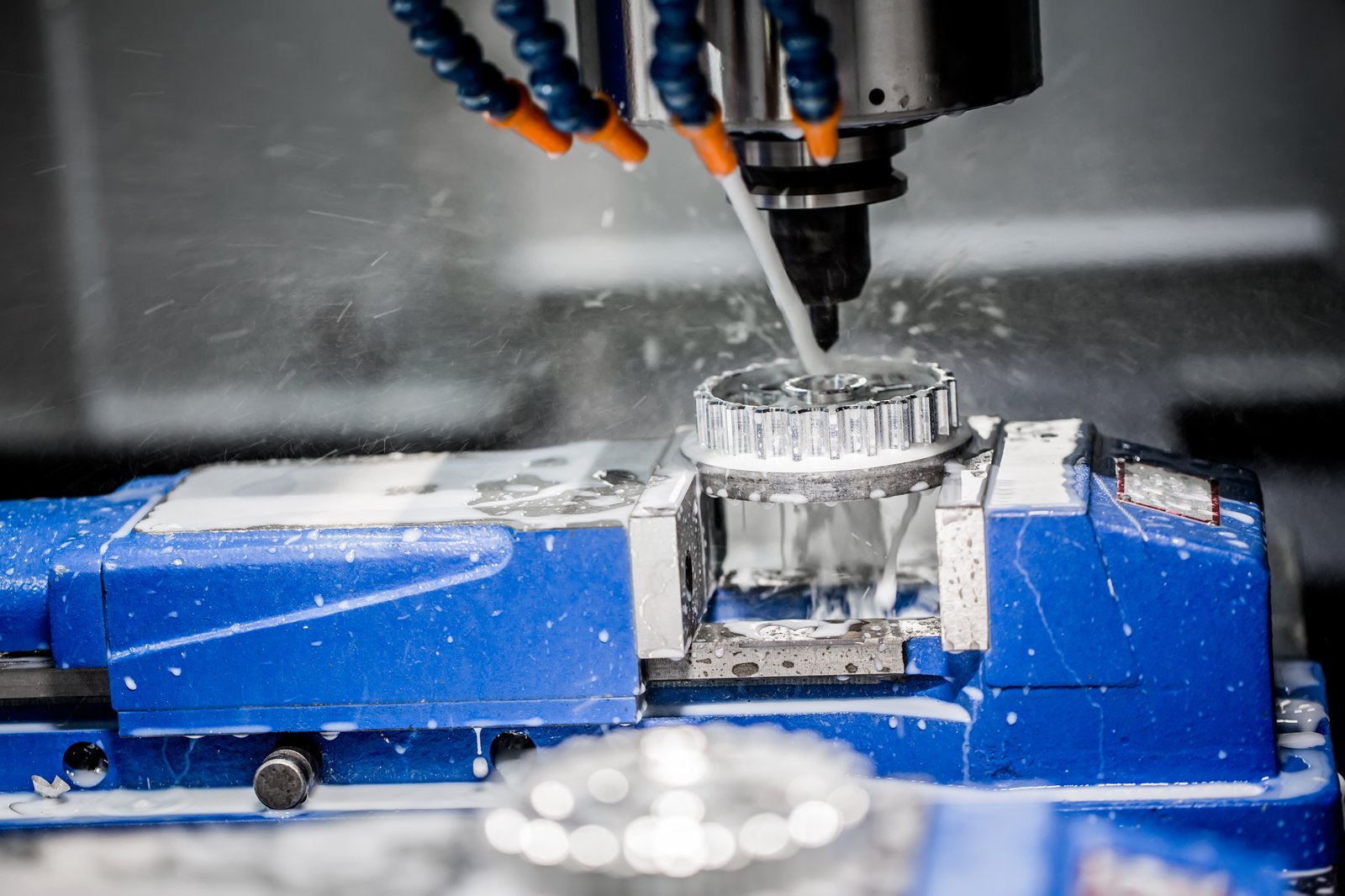

- Managing assets and maintaining them: In a manufacturing setup, it is essential to ensure that your equipment in good shape. Which means, efficient management of the asset usage, scheduling downtime, and stocking enough spares. Asset management capabilities should be part of your solution. This feature will enable you to gather data and process them even from customer premises. You can analyze the data to look at deviations, monitor performance levels, quality issues if any, and all other aspects. These insights will enable you to move from reactive maintenance to proactive and predictive maintenance to help reduce the downtime.

The way forward to ensure that your manufacturing unit performs at maximum efficiency is by ramping up the productivity with these five features.

Improve the efficiency of your manufacturing business.