Many equipment manufacturing companies are providing maintenance, upgrade, and other services to meet customers’ needs throughout the life of their products. More and more manufacturers are implementing full-fledged servitization, where they provide a service to deliver the business result or the benefit value a customer required, and that service includes product items together, for instance, with timely, proactive maintenance and continuous product enhancements.

In To-Increase Industrial Equipment Manufacturing 2016 for Microsoft Dynamics NAV, it has become far easier for manufacturers to run production and service management in an integrated, efficient manner.

Understanding and creating Service Objects

In this release, the solution comes with a new entity, the Service Object. You define what a Service Object is; it might be, for instance, a single machine, a facility where you install equipment, or a business group or organization that uses your products. There are two ways to create Service Objects:

From a Job Deliverable. This entails just one simple step, because Jobs and Service in Industrial Equipment Manufacturing are now integrated. The solution maintains a one-to-one relationship between Job Deliverables and Service Objects, and gives each its own number series.

Service Objects aggregate Service Items, and you can also nest or embed several Service Objects within each other. When you prepare a service contract, you can simply select a Service Object to insert all Service Items linked to it on a contract line. As you see, the service management capability in Industrial Equipment Manufacturing 2016 mirrors the functionality in Advanced Job Management, where Job Deliverables consist of Job Items.

From Job Items. Because your Service Items are closely related to Job Items, you can also create a new Service Item by means of a new Action in the Job Item list. In the Job Item list those entries are highlighted which are associated with a Service Item group and have the option Create as Service Item That means you can immediately see which Job Items are to be transitioned into Service Items.

Service Items are always unique. Therefore, if you use more than one Job Item within a Job, you will also be creating the corresponding number of Service Items.

Extending service management into mobility with a Time Registration app

When it comes to service delivery, many employees are always out in the field, working on customer sites or traveling from one to the other. You want to keep their momentum going and free them from administrative distractions that cut into their productivity. One way to accomplish that is to take advantage of modern mobility to help them record their time.

The new Time Registration app that is part of the Industrial Equipment Manufacturing 2016 release is designed to inter-operate with the resource tasks in the solution’s Resource Management. The app can also work offline. Synchronization between Resource Management and the Time Registration app takes place in the background without slowing down any actions on mobile devices.

The home page in the Time Registration app

Time registration in Resource Management is synced with the time input line in the app. When you process time input lines into time sheets, you can do so either manually, which gives you the opportunity to review before you create time sheet lines, or as a batch through a Job Queue.

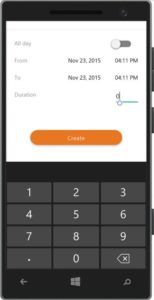

Using the Time Registration app to record the duration of a task

As we hear from our early-adopter customers, extending Resource Management into the mobile arena through the app also proves valuable outside of the mobile service delivery team. Some companies, for example, have made the Time Registration app available to their design engineers to make it easy for them to record the time they spend on specific projects.

Other blog posts about Industrial Equipment Manufacturing 2016:

(January 22)

Do you like what you see about service management in Industrial Equipment Manufacturing 2016? If you want to explore it more in-depth, please fill the form below to schedule an appointment with one of our industry experts.. You can also connect with me on LinkedIn and Twitter.